CURRENT PRODUCTION TIME IS 1-2 DAYS

FREE SHIPPING on Orders of $200 USE CODE SHIPFREE

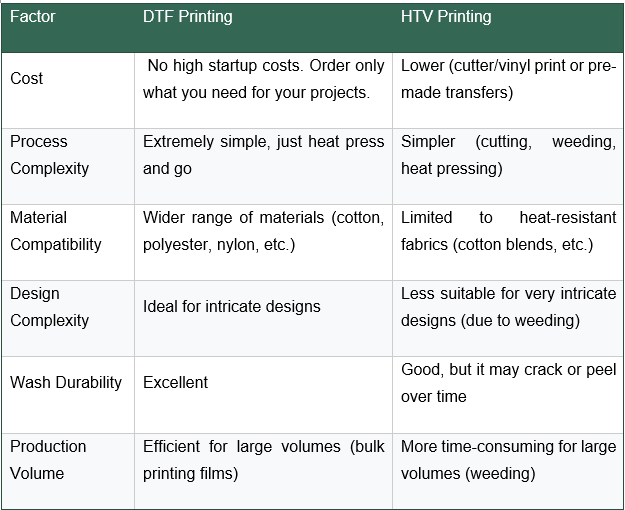

Choosing the right printing technique can make all the difference. Two popular options are Direct-to-Film (DTF) and Heat Transfer Vinyl (HTV) printing. Both offer unique advantages and disadvantages, and the best choice for you depends on your specific project needs.

Let’s explore the pros and cons of DTF and HTV printing. We’ll delve into the ease of use, material compatibility, durability, and cost-effectiveness of each method.

Whether you’re an experienced printing professional or just starting your journey into personalized garments, this information will equip you to make an informed decision for your next creative project.

DTF (Direct-to-Film) printing has emerged as a game-changer in the world of custom printing. Here’s why it might be the perfect fit for your project:

Forget the tedious weeding process associated with HTV. DTF printing eliminates this step entirely. Your design gets printed directly onto a special PET film, saving you valuable time and frustration. Imagine creating intricate designs without the need for meticulous weeding – a dream come true for both beginners and seasoned decorators alike.

Unleash your creativity on a wider canvas! Unlike HTV’s limitations on fabric types, DTF printing thrives on its adaptability. Cotton, polyester, nylon, even leather—DTF handles them all with ease. This opens doors for personalizing a vast array of products, from classic t-shirts and hoodies to hats, phone cases, and even sneakers.

DTF prints are built to last. The ink bonds seamlessly with the fabric, resulting in exceptional wash resistance. You can expect your designs to stay vibrant and crack-free, even after multiple washes. This makes DTF ideal for garments that experience frequent wear and tear, ensuring your creations remain cherished for longer.

Depending on your project volume, DTF printing can be more economical compared to other methods.

With DTF, bulk printing large quantities of designs onto film becomes an option. You can then store these pre-printed films for future use, streamlining your workflow and potentially reducing per-print costs.

While DTF printing shows impressive advantages, it’s important to approach it with a balanced perspective. Here are some potential drawbacks to consider:

The internet can be a treasure trove of information, but it can also be a breeding ground for inaccuracies. Due to the relative newness of DTF printing, especially in the US market, there’s a surprising amount of misinformation online. This can be confusing for beginners, making it essential to rely on reputable sources for your DTF printing education.

Heat Transfer Vinyl (HTV) printing offers a compelling solution for those seeking a user-friendly and cost-effective approach to garment customization. Here’s how HTV can empower your creative endeavors:

Compared to DTF’s initial investment, HTV printing is easier on the wallet. You have two main options: purchasing a cutting machine (like a Cricut) and printable heat transfer vinyl rolls or opting for pre-made heat transfer designs. This flexibility allows you to tailor your setup to your budget and project needs.

HTV printing is a relatively straightforward process, making it ideal for beginners or those new to the world of custom apparel. The core steps involve designing your artwork, cutting it out of printable vinyl using a machine or using pre-cut designs, and then DTF heat press them onto your chosen fabric. With minimal equipment and a manageable learning curve, HTV printing allows you to jumpstart your creative journey with ease.

Unleash your inner artist with the vast selection of HTV options available. From classic solids and metallics to vibrant neons, heat transfer vinyl comes in a spectrum of colors to suit any design vision. You can even find specialty printable HTV vinyls like glitter, holographic, or flocked textures, adding a unique touch to your creations. This variety empowers you to personalize garments that truly reflect your style.

While HTV printing offers a user-friendly and budget-conscious approach, it’s essential to consider its limitations:

Unlike DTF’s adaptability, HTV has limitations on compatible fabrics. It works best with heat-resistant materials like cotton and polyester blends. Attempting to use HTV on fabrics with low melting points can lead to scorching or damage. Understanding these material restrictions is crucial to ensure successful and long-lasting results.

For intricate designs, HTV’s weeding process can be a time-consuming hurdle. Weeding involves meticulously removing excess vinyl paper around your design after cutting it out. Complex designs with fine details can translate to significant weeding time. This might not be ideal for projects with tight deadlines or those featuring intricate artwork.

While printable HTV offers decent wash resistance, it doesn’t quite match the durability of DTF prints. Over time, repeated washing and wear can cause HTV designs to crack, peel, or fade. This is especially true for designs with intricate details or those applied to high-friction areas of garments. If long-lasting results are a top priority, DTF might be a better choice.

Now that we’ve explored the strengths and weaknesses of both DTF and HTV printing, it’s time to navigate the exciting world of choosing the right method for your project. Here’s a quick breakdown to guide your decision:

Go for DTF Printing if:

Go for HTV printing if:

Material compatibility aligns with your project (heat-resistant fabrics like cotton blends)

Whether you’re a seasoned decorator or a curious beginner, DTF and HTV printing offer exciting avenues to unleash your creativity.

By understanding the strengths and weaknesses of each method, you can make an informed decision that aligns with your project goals and skillset.

Remember, there’s no single “right” answer. DTF printing empowers you with efficiency, versatility, and long-lasting results, while HTV heat press offers a user-friendly and budget-conscious approach. Embrace the learning process, and don’t be afraid to experiment!

For further exploration, consider researching online tutorials or attending workshops specific to DTF or HTV printing. There’s a wealth of information and resources available to guide you on your creative journey.

With the right method at your fingertips, you’ll be well on your way to personalizing garments, accessories, and more, transforming them into unique reflections of your style and vision. Happy printing!

DTF printing, or Direct-to-Film printing, involves printing a design on a special film with ink. This design is then heat-pressed onto fabric like shirts.

DTF stands for Direct to Film, indicating the process of printing directly onto a film for transfer.

DTF printing works in a few steps. The design is printed on film with special inks. Then, powder is applied to the ink for adhesion. After that, the design is cured with heat. Lastly, the design is heat-pressed onto the fabric.

Heat transfer vinyl (HTV) involves pre-cut designs made from a vinyl material. You place the HTV on your fabric, then use a heat press to apply it. Unlike DTF, HTV requires weeding out excess vinyl around the design.